charpy impact test orientation|charpy v notch testing : supermarket The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. 3 de ago. de 2023 · Conheça a melhor e mais completa planilha iptv da atualidade. Perfeita para gerenciar seus clientes, revendedores, controle dos créditos do seu painel, contr.

{plog:ftitle_list}

web29 de jul. de 2014 · Fearing for his life, Atahualpa told Pizarro if he would spare him, within two months his people would fill a room 24-feet long by 18-feet wide and a height of 8-feet .

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's . The sample shape required to perform a Charpy test is very simple. The samples are rectangular in size (measuring 127mm in legnth and 12.7mm in width) and have a nominal .

This paper presents the experimental analysis which included impact toughness test. The analysis resulted in impact energy values, and their respective components, crack .The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture.The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

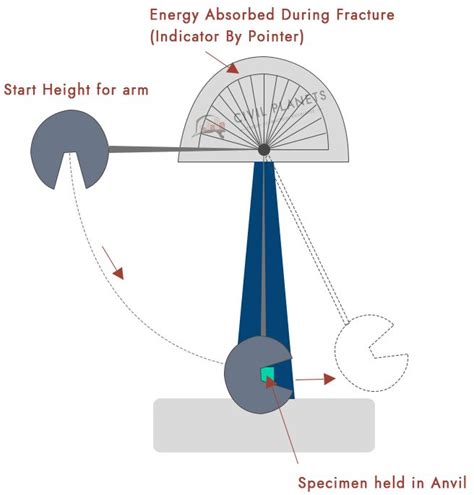

A Charpy Impact Tester is a specialized machine designed to measure the impact toughness or resistance of materials. It evaluates how effectively a material can absorb energy during sudden loading, such as when .

This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen .Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.

The Charpy impact test was performed after extracting samples in directions both parallel and perpendicular to the deposition direction. . The effect of notch orientation (longitudinal-radial (L .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps .

Given that Charpy impact testing has a much higher strain rate than quasi-static tension [76], strain localization is more likely to occur during Charpy impact testing. As a result, the 〈110〉 samples were more prone to premature fracture, especially at the V-notches, causing their lower absorbed energy at RT compared with the other samples.The dependence of the mechanical properties respect to the microstructural orientation of a low carbon steel API-5L grade X46 pipe was assessed by Charpy impact and tensile strength tests, through .

The diagram below shows the grain direction for longitudinal and transverse charpy tests. If the grain direction for the charpy test is not in either of the orientations shown, but is instead coming out of the page (orthogonal to both orientations shown), would that also be classified as a transverse test or would it be something else?One of the main differences from Charpy impact is that Izod impact testing is performed in two orientations on the same sample whereas the Charpy test is performed in the same orientation. Plastic samples are typically a 64 x 12.7 x 3.2 mm bar with a machined V-shaped notch.

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch. The Testing Process. Understanding how a Charpy Impact Test works requires familiarity with its testing process: 1. Preparing the Test Specimen: Before commencing any tests, it’s essential to prepare suitable test specimens according to specific standards or requirements related to size, shape, notch geometry, and orientation. 2.

The hot-press-forming (HPF) steels might contain a few MnS inclusions, and their brittle characteristics and stringer shape can deteriorate the impact toughness and formability. In this study, effects of shape and orientation of MnS particles on Charpy impact and bending properties of 1470-MPa-grade HPF steel sheets were investigated by conducting ex situ three .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its behavior under sudden loading. This test is crucial in assessing the suitability of materials for applications . The Testing Process. Understanding how a Charpy Impact Test works requires familiarity with its testing process: 1. Preparing the Test Specimen: Before commencing any tests, it’s essential to prepare suitable test specimens according to specific standards or requirements related to size, shape, notch geometry, and orientation. 2.

A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . Small changes in initial drop height, test specimen preparation, and test specimen orientation can drastically impact testing results. Test machine .

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.Download scientific diagram | Charpy impact test configuration: Loading directions with respect to the sample multilayer structure from publication: Injection moulding of long glass fibre .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away . Charpy Impact Testing Standards. ASTM E23: Notched bar impact testing of metallic materials; DIN EN ISO 148-1 2011: . Destructive tests on welds in metallic materials- impact testing- test specimen location, notch .

Download scientific diagram | Charpy impact testing: a) as a function of temperature; b) as a function of the orientation (for some temperatures). from publication: Microstructure and Microtexture .The most popular impact tests are the Charpy test and the Izod test. These two tests determine essentially the same material characteristics, but differ in the orientation of the test sample, which causes the sample to be stressed in different directions and involves a known weight released from a known height colliding with the sample in its test structure.Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

Charpy Impact Test: In this method, a test specimen is held at one end and struck on the opposite end with a pendulum hammer. The amount of energy absorbed by the specimen during fracture is measured. . Specimen orientation: In the Charpy Impact Test, the specimen is placed horizontally and the hammer strikes the side opposite the notch. In . Parts printed at a 45° orientation demonstrated superior mechanical strength to those printed at a 90° orientation. Lambiase et al. . This study selected the impact strength obtained from the Charpy impact test applied to the FDM-produced tough PLA specimen groups as the performance characteristic. High Charpy impact strength will ensure .4.3 The Charpy V-notch impact test in relation to other tests. 4.4 Factors influencing impact properties. 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces.

changing the orientation of the molecules or by using fibrous fillers. Most polymers, when subjected to impact load, seem to fracture in a well defined way. Due to the impact load, . Charpy) impact test. All the test variables that have a . The orientation of Charpy specimens for impact testing is shown in Fig. 3. The prepared test specimens were cut from the middle of thickness with notched roots located in the BM, SW, and GW (Fig. 8). Charpy impact tests were carried out at temperatures ranging from − 80 to 20 °C to produce a complete absorbed energy curve data in order to .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .At the heart of the Charpy test is the Charpy Impact Testing Machine. During the test, a pendulum arm is raised to a predetermined height and then released to strike the specimen with precision. . Its orientation may vary depending on specific requirements and norms. Temperature Variation: Causes of Variable Specimen Temperatures. The Charpy .

what is the charpy test

charpy v notch testing

WEBSalmos 14. Ouvir. 1 Diz o tolo em seu coração: "Deus não existe". Corromperam-se e cometeram atos detestáveis; não há ninguém que faça o bem. 2 O Senhor olha dos .

charpy impact test orientation|charpy v notch testing